Cultivated Meat & Seafood

Study reveals antimicrobial solution for cultured meat

Siân Yates

21 February 2025

21 February 2025

Study reveals antimicrobial solution for cultured meat

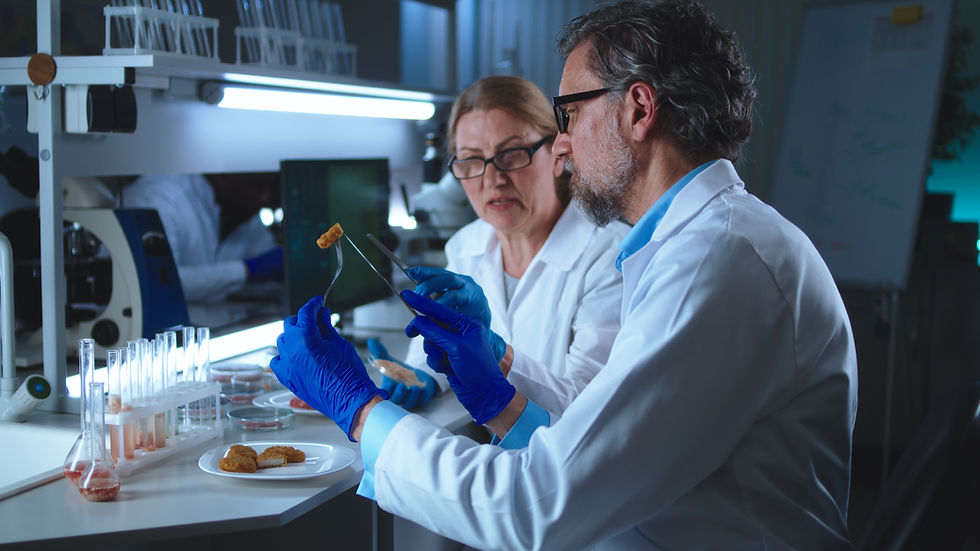

Researchers from The Hebrew University of Jerusalem have identified a promising alternative to traditional antibiotics in the production of cultured meat.

The study, published in Food Chemistry: Molecular Sciences, explores the use of random antimicrobial peptide mixtures (RPMs) as effective agents against microbial contamination, a persistent challenge in cellular agriculture.

Antibiotics have been a common tool in cell culture settings to prevent bacterial contamination. However, their use raises critical concerns regarding antibiotic residues in food products and the potential for developing antibiotic-resistant bacteria, which poses a significant public health threat.

With the cultured meat industry poised for growth, addressing these concerns is essential for ensuring consumer safety and regulatory compliance.

The research team investigated the efficacy of RPMs – synthetic peptide cocktails that exhibit broad antimicrobial activity.

The study revealed several key findings:

Bactericidal activity: RPMs demonstrated strong antibacterial effects against both Gram-positive bacteria, such as Listeria monocytogenes, and Gram-negative bacteria, including Escherichia coli. The RPMs effectively inhibited bacterial growth without compromising the viability of mesenchymal stem cells (MSCs), which are crucial for cultured meat production.

Safety profile: The RPMs did not induce significant toxicity in MSCs, even at concentrations effective against bacterial pathogens. This indicates a favorable safety profile for potential incorporation into cultured meat production systems.

Resistance development: Unlike conventional antibiotics, RPMs exhibited a low occurrence of bacterial resistance. This characteristic is vital for the long-term sustainability of antimicrobial strategies in food production.

Digestibility: The RPMs were rapidly digested in simulated gastrointestinal conditions, suggesting they would not pose risk of bioaccumulation or adverse effects on human health.

The findings from this study present a compelling case for the adoption of RPMs in the cultured meat industry. As food manufacturers increasingly focus on sustainability and food safety, the ability to utilise non-antibiotic antimicrobial agents could enhance product integrity while addressing regulatory and consumer concerns.

The application of RPMs could significantly streamline the production process by minimising the risks associated with microbial contamination, ultimately supporting the scalability of cultured meat operations.

This development aligns with the broader industry trends toward cleaner, safer food production methods that prioritise both environmental sustainability and public health.

The research team, led by Professor Zvi Hayouka, is exploring the industrial applications of RPMs and the regulatory pathways necessary for their integration into commercial cultured meat production. The goal is to facilitate broader adoption of this innovative antimicrobial strategy within the alternative protein sector.

Related news

Cellular Agriculture opens bioreactor access through Campden BRI partnership

A new Innovate UK–funded collaboration will give food and biotech companies access to Cellular Agriculture’s next-generation bioreactor system without the need for upfront investment.

Cellular Agriculture achieves milestone with world’s longest hollow fibre bioreactor runs

Cellular Agriculture has completed multiple runs of what it claims is the world’s longest hollow fibre bioreactor for any cell culture application,

Cellular Agriculture expands into new R&D base, eyes Q1 2026 pilot-scale launch

Cellular Agriculture has relocated to a purpose-built research and development facility at Corsham Science Park, Wiltshire, marking a significant expansion of its capabilities as it prepares to scale cultivated food technologies.

Cultivated Meat & Seafood

Study reveals antimicrobial solution for cultured meat

Siân Yates

21 February 2025